Lean Management is a managerial philosophy aimed at delivering the maximum possible value to the customer using the minimum resources. It is based on a simple yet profound principle: “Any activity that does not add value from the end customer’s perspective is waste that must be eliminated.”

1. The Five Principles of Lean

-

Define Value: Understanding exactly what the customer is willing to pay for.

-

Map the Value Stream: Identifying all steps in the process and highlighting non-value-adding tasks.

-

Create Flow: Ensuring work moves smoothly from one stage to another without interruption.

-

Establish Pull: Starting new work only when there is actual demand.

-

Pursue Perfection: Continuous improvement to reach zero waste.

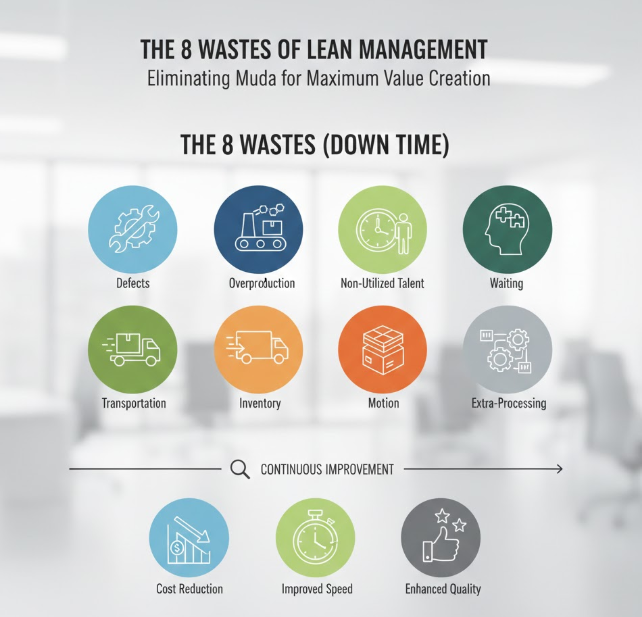

2. The Eight Types of Waste

Lean identifies eight “enemies” of productivity:

-

Defects: Time spent fixing errors.

-

Overproduction: Doing more work than required.

-

Waiting: Time lost waiting for approvals or resources.

-

Non-utilized Talent: Failing to use the team’s full potential.

-

Transportation: Unnecessary movement of info or materials.

-

Inventory: Accumulation of unfinished tasks.

-

Motion: Unnecessary physical movement of people.

-

Extra-processing: Adding features the customer didn’t ask for

3. Benefits of Applying “Lean” in Projects

-

Cost Reduction: By eliminating non-essential activities and saving wasted resources.

-

Improved Speed: Completing tasks in less time thanks to a smooth and continuous workflow.

-

Enhanced Quality: Focusing on value leads to fewer errors and higher customer satisfaction.

Lean management is a mindset focused on working smarter, not harder. A Lean manager is someone who can see hidden waste and purify processes, keeping the team agile, fast, and focused entirely on delivering customer satisfaction.